Designed to Scale

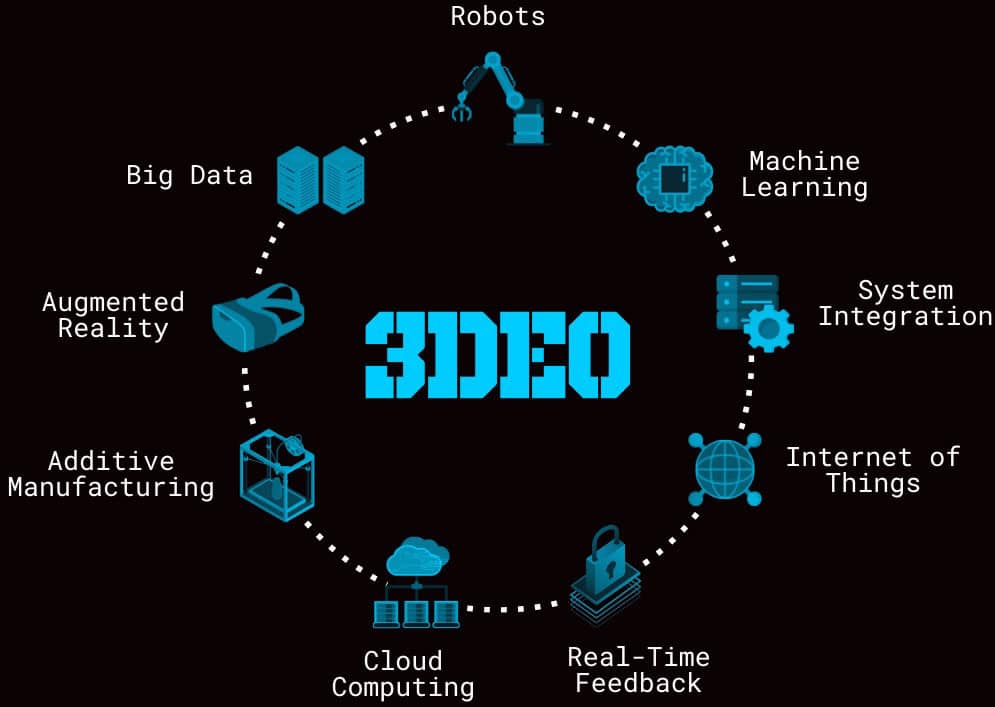

3DEO was founded on the vision to become the premier metal 3D printing part service to successfully combine mass production metal 3D printing capabilities with multi-disciplinary design and product development expertise.

Keeping customers’ pain points and overall goals in mind, 3DEO approaches each unique customer problem with a collaborative mindset and specialized additive knowledge to ensure optimal design solutions, part performance and operational efficiencies are applied to their products. The team at 3DEO works directly with customers to coordinate on-schedule deliveries and ensure timelines are met so that product teams can worry about what matters most: a successful launch at scale.

Co-founder and former CEO Matt Petros discusses how 3DEO’s holistic approach to manufacturing differentiates the company in the industry.

Automation Where You Need It.

Collaboration Where You Want It.

3DEO’s dedicated team of engineers understands the product innovation process, partnering with customers along various points of their product development journey, and helping them launch and scale products with a competitive edge. As innovators themselves, 3DEO is one of the only end-to-end design and manufacturing services that uses its own proprietary technology and automation platform to provide high quality parts that are consistent from first articles through to production at scale.

3DEO’s History

From its very first prototype printer to its full-scale automated factory, 3DEO has been helping engineering teams solve their toughest problems, enabling their companies to launch quality products with a competitive edge.

2016

2018

2020

2022

2024

2017

2019

2021

2023

3DEO’s History

From its very first prototype printer to its full-scale automated factory, 3DEO has been helping engineering teams solve their toughest problems to better enable their companies to launch quality products with a competitive edge.

2016

2017

2018

2019

2020

2021

2022

2023

2024

COMPANY CULTURE

Team 3DEO

From hiring its first 2 employees to taking off as one of the highest volume 3D printing companies in the world, 3DEO has continued to invest in its company culture through diversity and inclusion initiatives, team events and outings, and community engagement. 3DEO is an American manufacturing company with its primary factory based in Torrance, CA.

Senior Leadership

STAY IN THE KNOW

Press Releases

Stay up to date with 3DEO’s latest announcements, releases and media alerts. For press inquiries, please contact Emily Elpes, Vice President of Marketing at [email protected].