3DEO VS. INVESTMENT CASTING

3DEO Customer Case Studies For Metal 3D Printing

Explore customer success stories and industry case studies featuring real parts from the production line.

Featured Case Study: Aerospace

As those who use investment cast parts in their products for the aerospace industry know, casting has always presented challenges: dimensional variation, post-processing steps, non-destructive testing requirements, and uncertainty in material properties.

3DEO was able to help this aerospace customer solve its challenges with their part and get their subassemblies back in production—which was the beginning of a true partnership. This customer is leveraging 3DEO’s resources in a way that is creating a long-term competitive advantage for the aerospace company, as they continue to bring additional components to be adapted from investment casting to additive manufacturing at scale. But what got the ball rolling?

Explore More Additive Manufacturing Case Studies

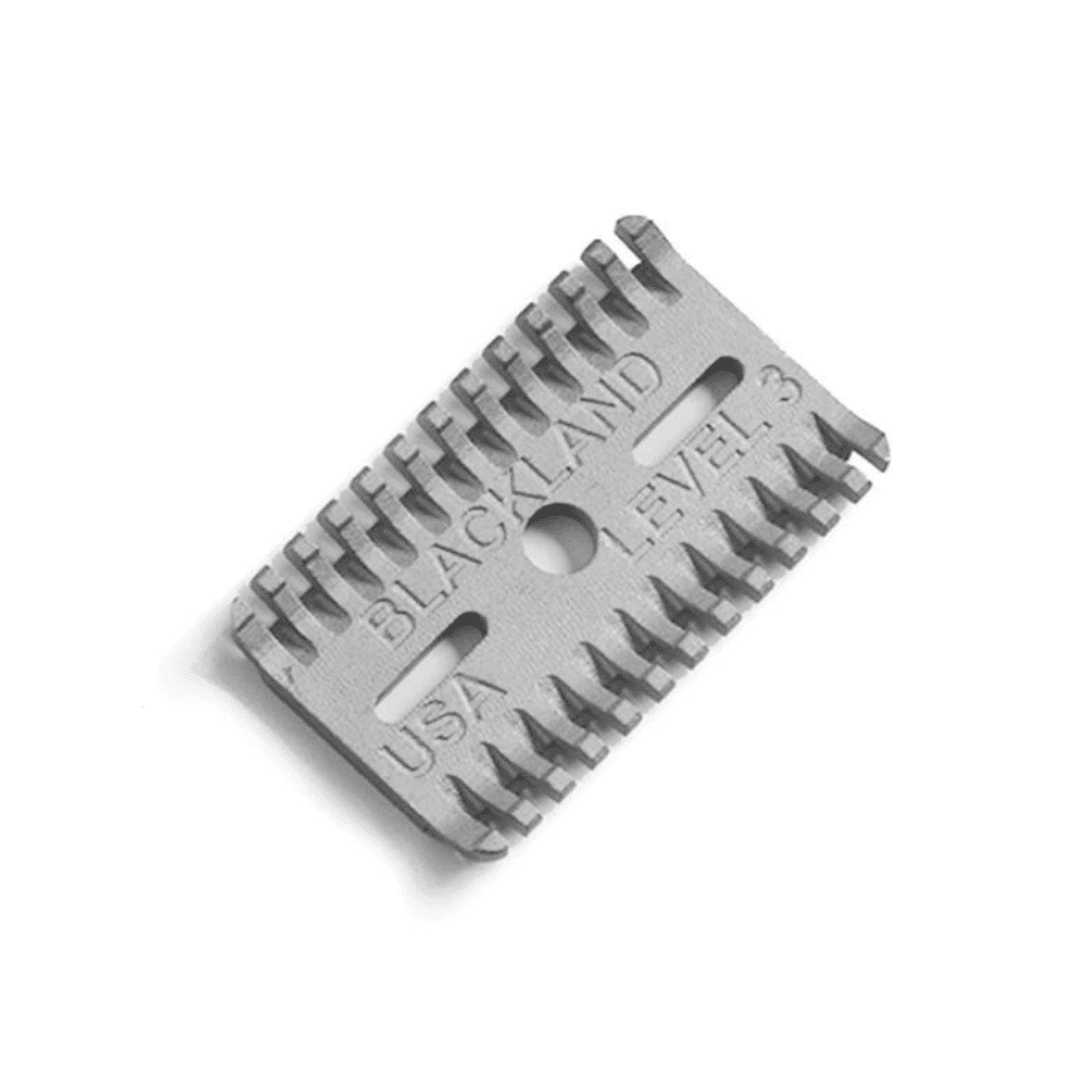

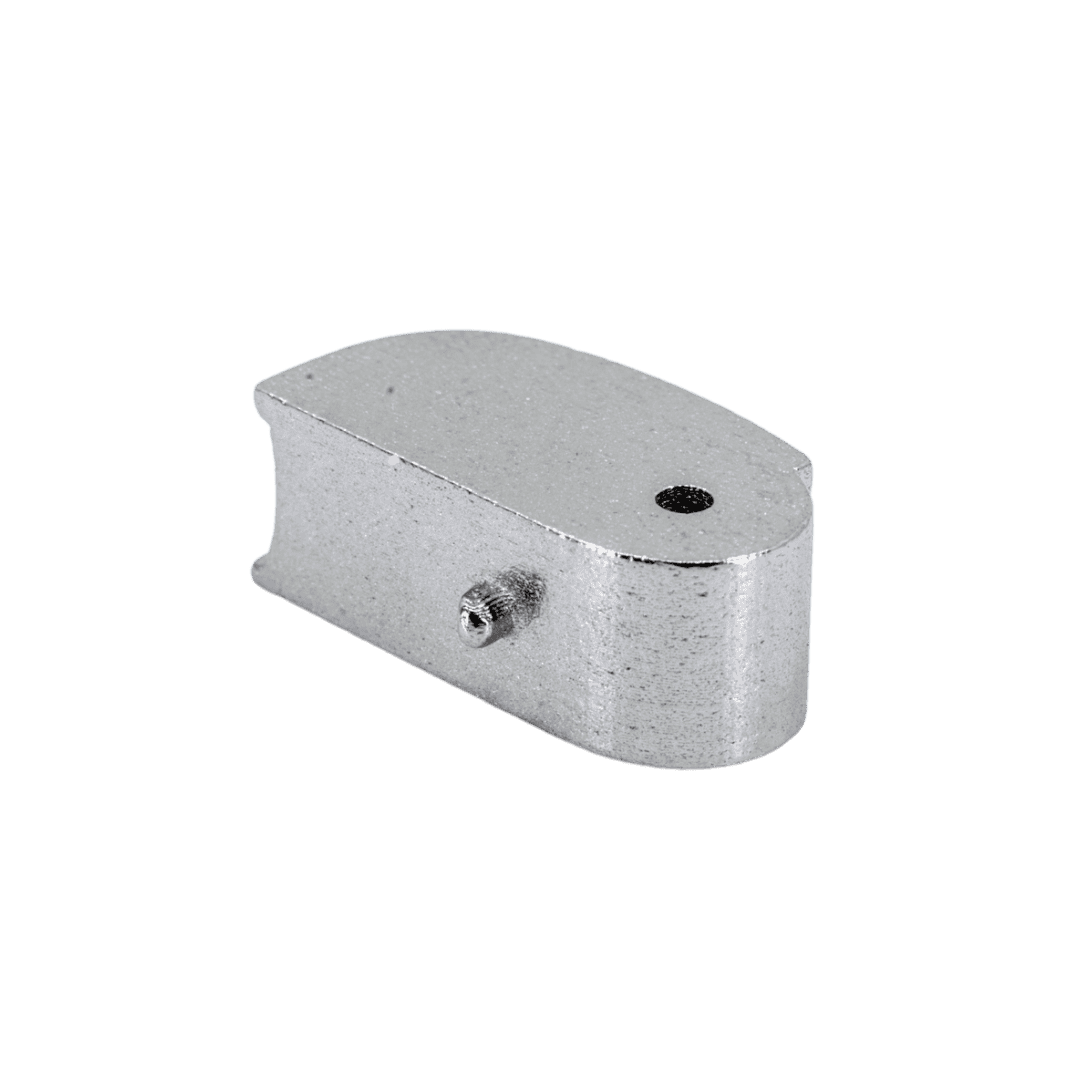

Latch

ErgoKiwi wanted to utilize metal 3D printing for a latch used in their ergonomic cutting tool. They were underwhelmed by the quality of another 3D printing service.