Metal 3D Printing Guide

GET YOUR GUIDE TO THE ECONOMICS

Metal Injection Molding Versus Metal 3D Printing

Why it matters: Manufacturers today who are searching for a cost-effective way to make small and complex metal parts for production by and large only have two options: metal injection molding (MIM) or investment casting. Metal 3D printing is the new entrant to the scene, and for the first time in a long while adds another option to the engineer’s toolkit.

Sign up and get your free guide

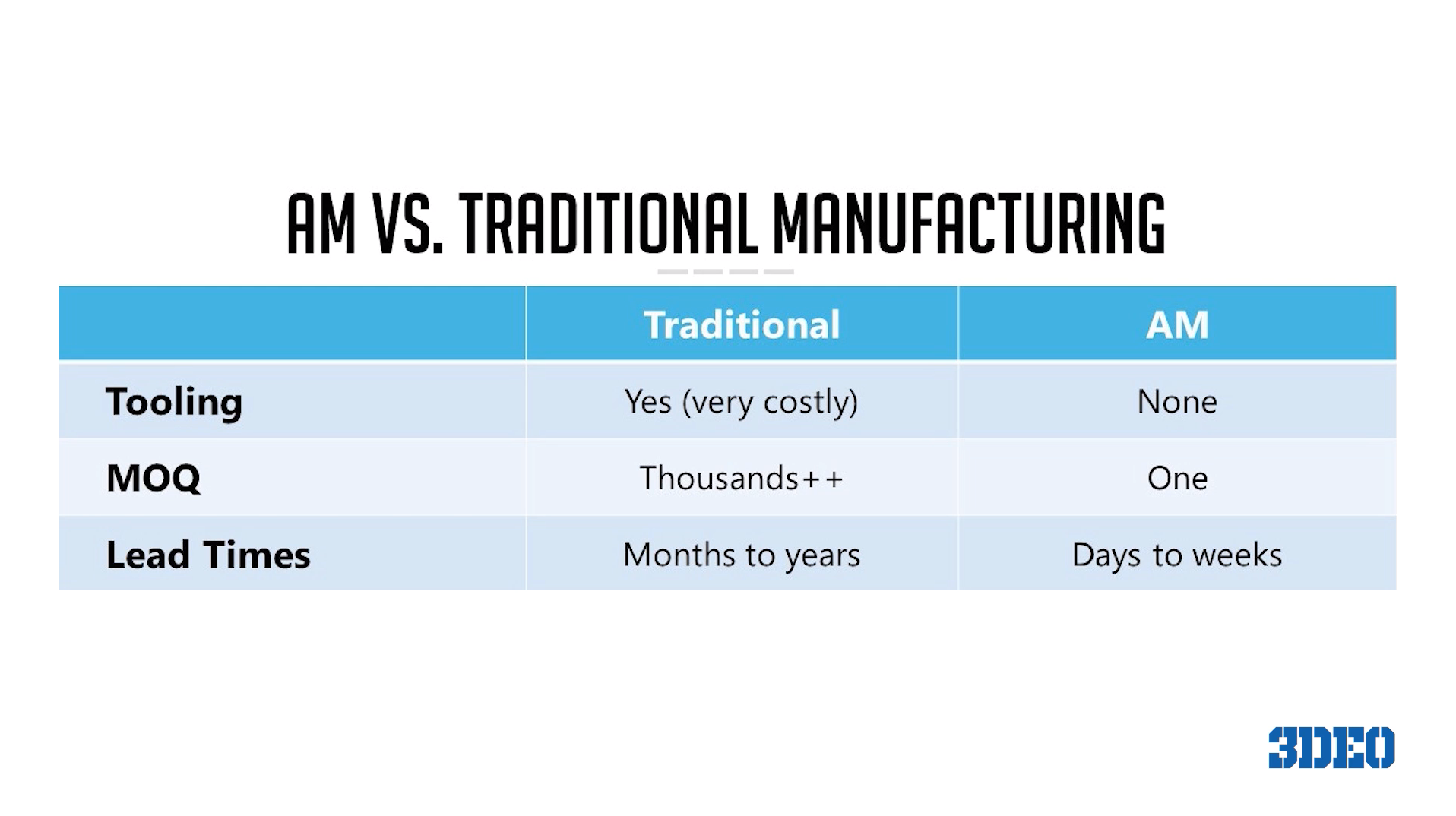

The Economics of Metal Additive Vs. Traditional Manufacturing

Manufacturers working on their new products and researching the most cost-effective way to manufacture small and complex parts need to be investigating three key benefits of bind & sinter technologies:

- No tooling, no need to buy expensive molds

- No minimum order quantities

- Shortened lead times