Featured by:

July 8, 2024

3DEO Wins Grand Prize at 2024 Design Excellence Awards

3DEO, the Torrance-based design, engineering, and manufacturing firm and a global leader in metal 3D printing, has once again demonstrated its industry leadership by winning the Grand Prize in the Medical/Dental Category for Metal Additive Manufacturing (AM) components at the PowderMet & AMPM2024 show held last month in Pittsburgh, PA. The company, along with a leading medical device manufacturer, was awarded for their bone marrow harvesters.

March 11, 2024

3DEO Partners with IHI AEROSPACE Co., Ltd. to Advance Aerospace Manufacturing Through Strategic Investment

3DEO is proud to announce a strategic partnership and investment with IHI AEROSPACE Co., Ltd (IA). This multifaceted, multi-phased partnership aims to enhance the adoption and implementation of AM technologies within IA, drawing on 3DEO’s expertise and resources in Design for Additive Manufacturing (DfAM) and technology differentiation to support its mission.

January 18, 2024

3DEO Secures Strategic Investment From Development Bank of Japan and Seiko Epson Corporation to Accelerate Growth and Innovation

3DEO today announced a significant investment from the Development Bank of Japan Inc. (DBJ) and Seiko Epson Corporation (EPSON). This partnership marks a pivotal step in 3DEO's expansion and underscores the confidence in its proprietary end-to-end 3D printing technology.

June 26th, 2023

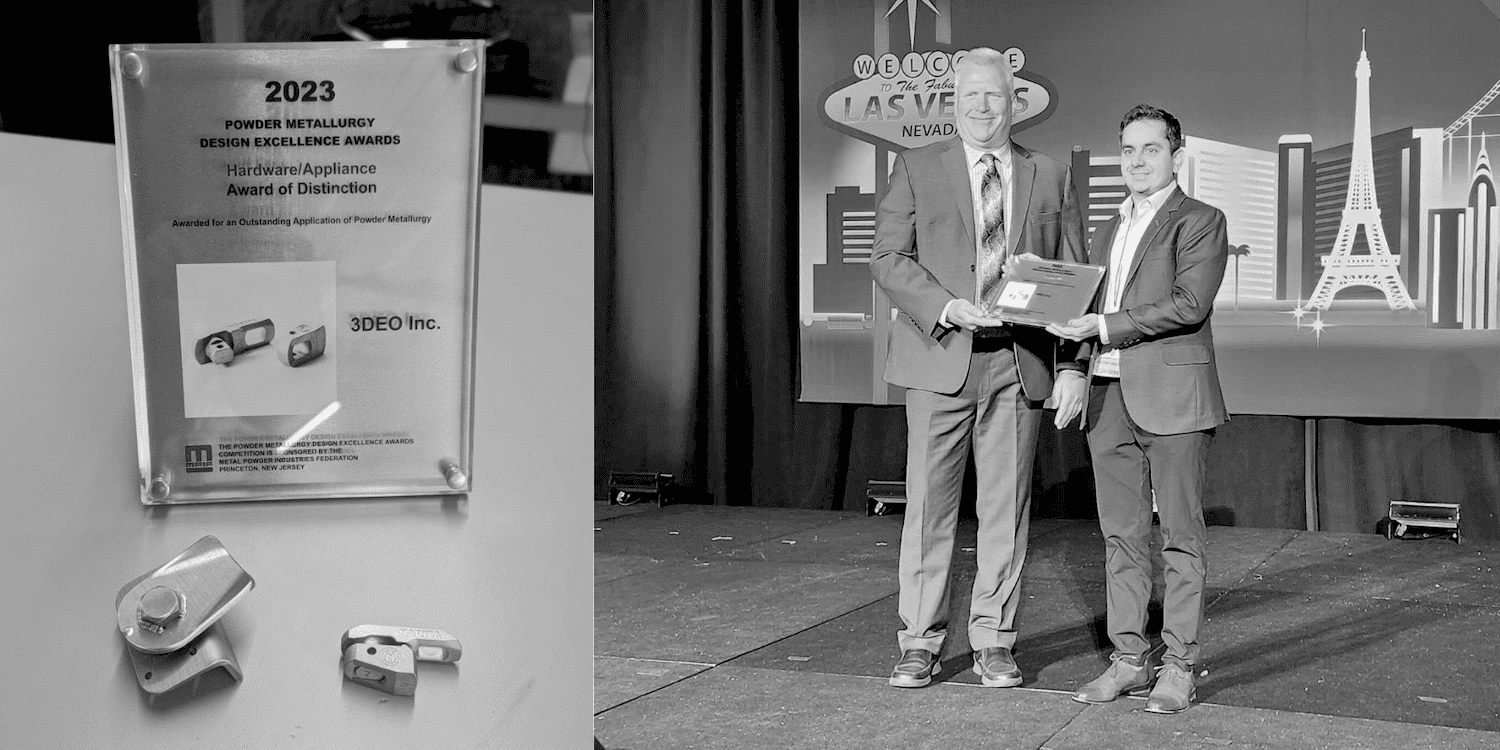

3DEO Wins Grand Prize at 2023 Design Excellence Awards

3DEO was recognized for outstanding application of powder metallurgy at the PowderMet & AMPM2023 show in Las Vegas, NV. The company won the Grand Prize for Medical/Dental Application and an Award of Distinction for the Hardware/Appliance Category at the 2023 Design Excellence Awards.

January 24th, 2023

3DEO Launches 316L Stainless Steel in High-Volume Metal 3D Printing

3DEO announced today the launch of 316L austenitic stainless steel. The new material is available to customers across all industries, especially in medical, industrial, marine and food processing. This weldable material is extremely corrosion resistant, which makes it ideal for applications that will experience harsh environments.

July 19th, 2022

3DEO Adds Design for Additive Manufacturing (DfAM) as Core Service

3DEO has added design and engineering services to better support its customers throughout the entire product lifecycle. 3DEO is introducing advanced end-to-end solutions to product and engineering teams across all industries, specializing in medical devices, industrial equipment, aerospace and consumer products.

June 9th, 2022

3DEO Named Category Winner at TCT Awards 2022

On June 8, 2022 in Birmingham, UK at the TCT Awards, 3DEO, one of the world’s highest volume metal 3D printing companies, won the TCT Consumer Product Application Award for their 3D printed production razor manufactured for Blackland Razors – “The Era.”

February 28th, 2022

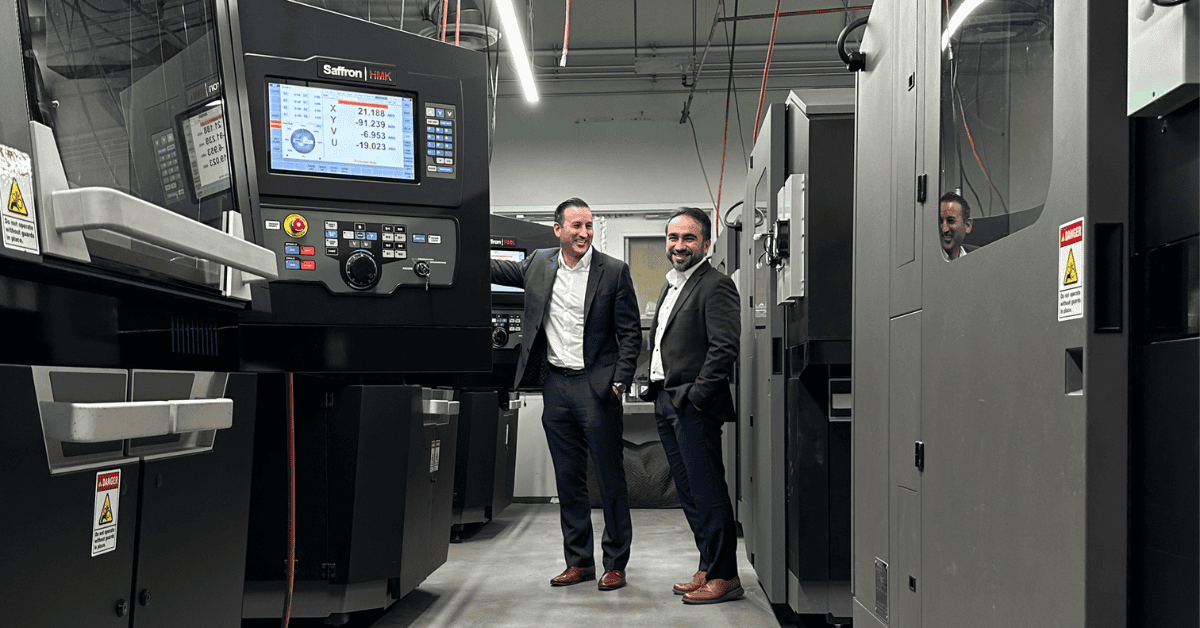

3DEO Hosts Press Conference: Unveils New Saffron Printer & Technology

In the midst of National Engineers Week, 3DEO, the world’s highest volume metal 3D printing company, hosted a hybrid press conference from their recently expanded 80,000 square foot facility in Torrance, California, to unveil their new 3D printing platform and patented technology, Saffron. Joined by Torrance Mayor Patrick Furey, 3DEO Co-founder and President Matt Sand spoke in detail about 3DEO’s award-winning, proprietary 3D printing process.

January 4th, 2022

2021 Year in Review: 3DEO Sets Records in Metal 3D Printing for Mass Production

3DEO has set a number of records in what was one of the most challenging and thrilling years in recent history for American-based manufacturing. The team as a whole expanded by 91% in 2021 to 175 total employees. 3DEO has more than 20 patents granted or pending across a wide range of applications including 3D printing, robotics, software and automation.

November 11th, 2020

3DEO Takes Gold Medal in the 2020 LEAP Awards for Additive Manufacturing

3DEO has won the Design Excellence Award for its metal 3D printed production component at the 2020 Design Excellence Award Competition. 3DEO production parts can be found in diverse industries and applications in the aerospace, medical device and consumer product industries.

August 6th, 2020

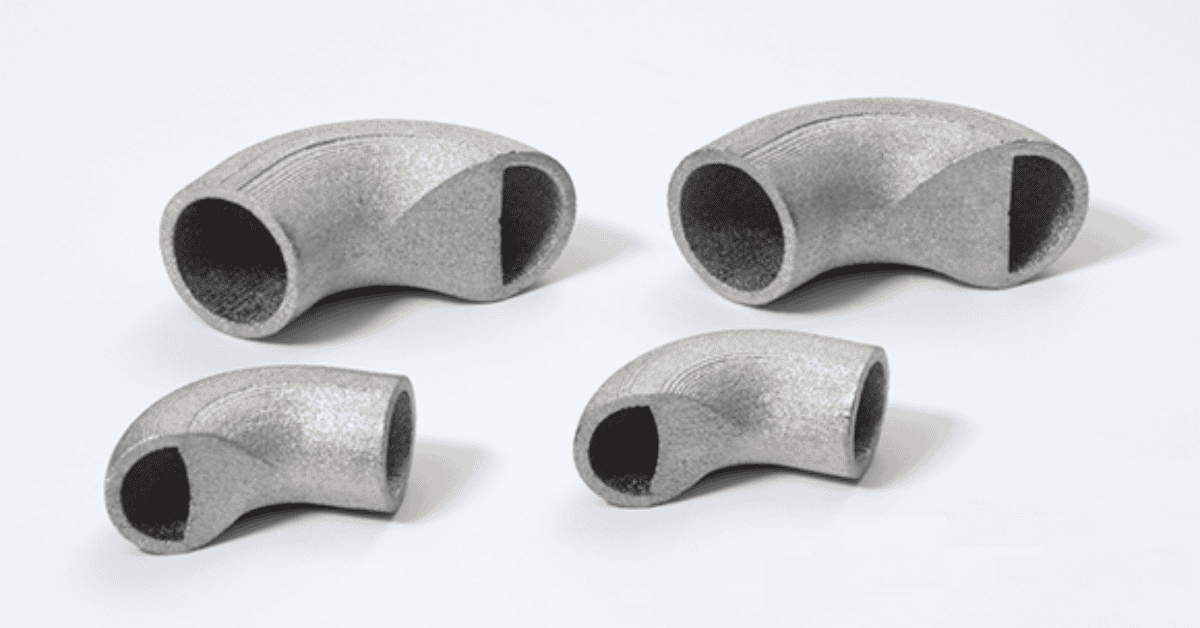

3DEO Wins MPIF Design Excellence Award

3DEO has won the Design Excellence Award for its metal 3D printed production component at the 2020 Design Excellence Award Competition. 3DEO production parts can be found in diverse industries and applications in the aerospace, medical device and consumer product industries.

June 9th, 2020

3DEO Ships 150,000 Production Parts, Breaking Ground in Metal Additive Manufacturing

3DEO has shipped 150 thousand production parts for end-use applications. This represents a significant milestone for the company, which was founded in 2016 specifically to compete in high-volume metal manufacturing markets against conventional manufacturing techniques like CNC Machining and MIM.

May 19th, 2020

3DEO Achieves ISO 9001:2015 for Quality Management Systems

A strong quality management system is the backbone of any world-class production line. The ISO certification marks an important step in realizing 3DEO’s long-term vision of leveraging next-generation technologies to build the world’s highest quality factory of the future.

May 5th, 2020

3DEO Posts Triple Digit Annual Growth with Next Generation Metal 3D Printing

Continuing its annual growth, 3DEO’s new business model has enabled a 600 percent increase in revenue for 2019 over 2018. This coincides with a 394 percent increase in the number of parts shipped in 2019 over 2018 as well. Approximately 35 percent of those parts were customers in the medical industry; 25 percent in aerospace.

March 7th, 2019

3DEO Honors Women’s Month 2019, Sponsors Women in 3D Printing

To maintain its rapid growth, 3DEO says it is committed to building a qualified and diverse team from all backgrounds; in fact, 23% of 3DEO’s team is comprised of women, with roles ranging from manufacturing to marketing. This puts 3DEO ahead of the 3D printing industry, which averages a female/male ratio of 13%.

February 26th, 2019

3DEO More Than Doubles Production Capacity in Q1 To Meet Demand

By all measures, 3DEO is rapidly expanding to fill a large void in the market of small complex metal parts. Customers are validating our technology across a variety of industries and we are either in production or quickly moving to production with many clients.