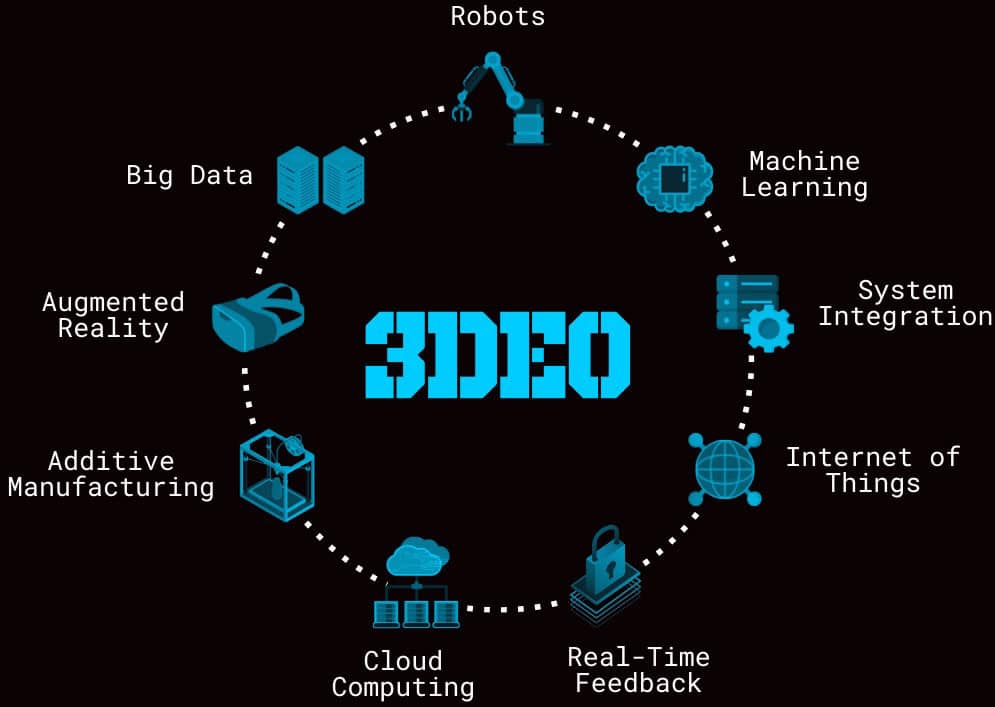

3DEO was founded on the vision to become the premier metal 3D printing part service to successfully combine mass production metal 3D printing capabilities with multi-disciplinary design and product development expertise.

Keeping customers’ pain points and overall goals in mind, 3DEO approaches each unique customer problem with a collaborative mindset and specialized additive knowledge to ensure optimal design solutions, part performance and operational efficiencies are applied to their products. The team at 3DEO works directly with customers to coordinate on-schedule deliveries and ensure timelines are met so that product teams can worry about what matters most: a successful launch at scale.