See the original blog article on LACE by Jenny Wu.

LACE by Jenny Wu is collaborating with additive manufacturing company, 3DEO, to unveil Link, a new 3D printed chain-link bracelet that combines LACE’s innovative jewelry design with the highest level of precision that is only made possible through 3DEO’s proprietary Intelligent Layering® technology. The design of Link completely redefines how a chain link is made traditionally, as each link connects to each other without any additional hardware, hinges or pin connectors. Because each link is an independent piece, it also allows for adjustability in terms of size as well as finishes.

“This collaboration has been several years in the making. I’m especially excited because 3DEO’s innovative technology allows me to produce an interlocking chain that I have not been able to do previously directly with 3D printing.” – Jenny Wu, founder of LACE

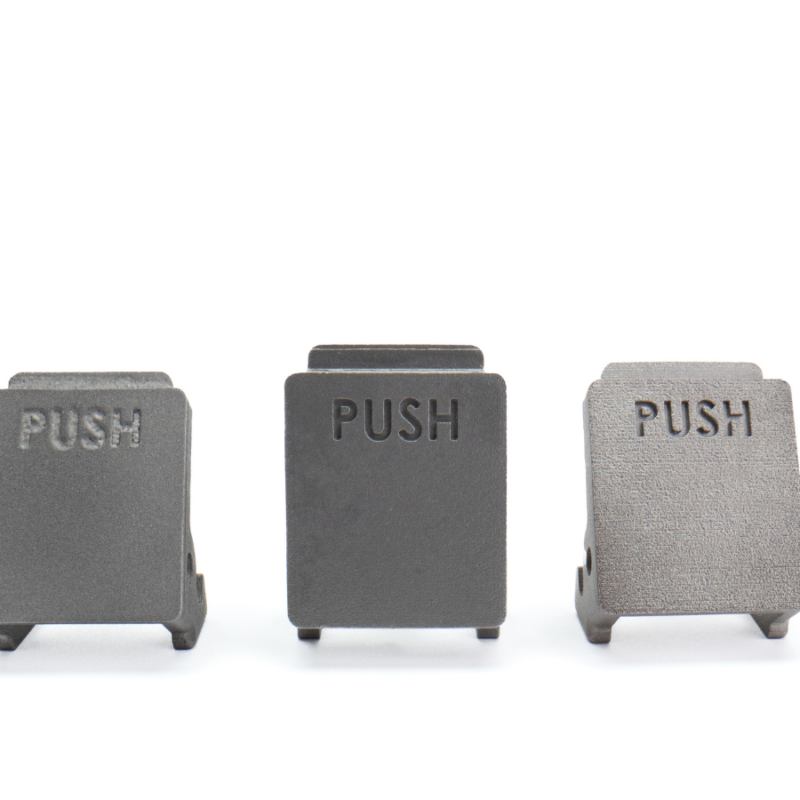

Above: Each link is connected through a ball joint that runs along an integral track on an adjacent link.

The chunky chain link bracelet has been an eye catching trend for the past year. LACE seeks to create new unique variations to this new classic. Link is produced from stainless steel 17-4PH which boasts high strength and corrosive resistance. It’s a material that has been used extensively in aerospace and medical industries. At its launch, Link is offered in 2 finishes, matte and polished, with new finishes to follow later this year. This unisex bracelet can be adjusted to fit all wrist sizes, as the links can be easily removed or added. With presale starting on January 24, Link will start shipping in early February.

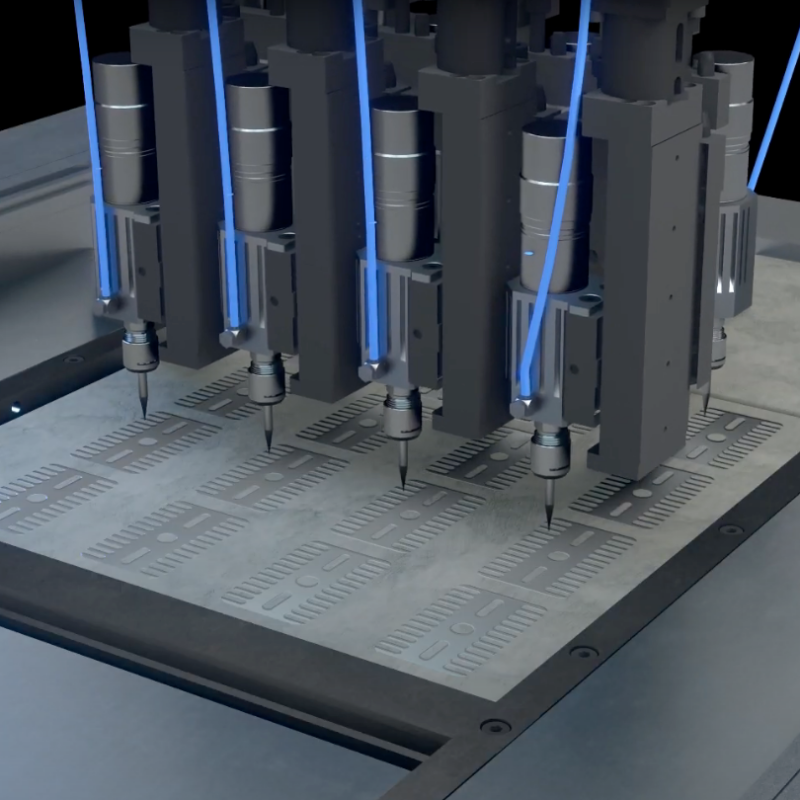

Intelligent Layering® Technology

Step 1: Slicing Parts and 3D Printing

Step 1: Slicing Parts and 3D Printing

The production process begins with 3DEO’s proprietary Intelligent Layering® technology. No extra support structures are needed as it prints, as the surrounding powder provides all the necessary support to print the part while simultaneously maximizing the build volume.

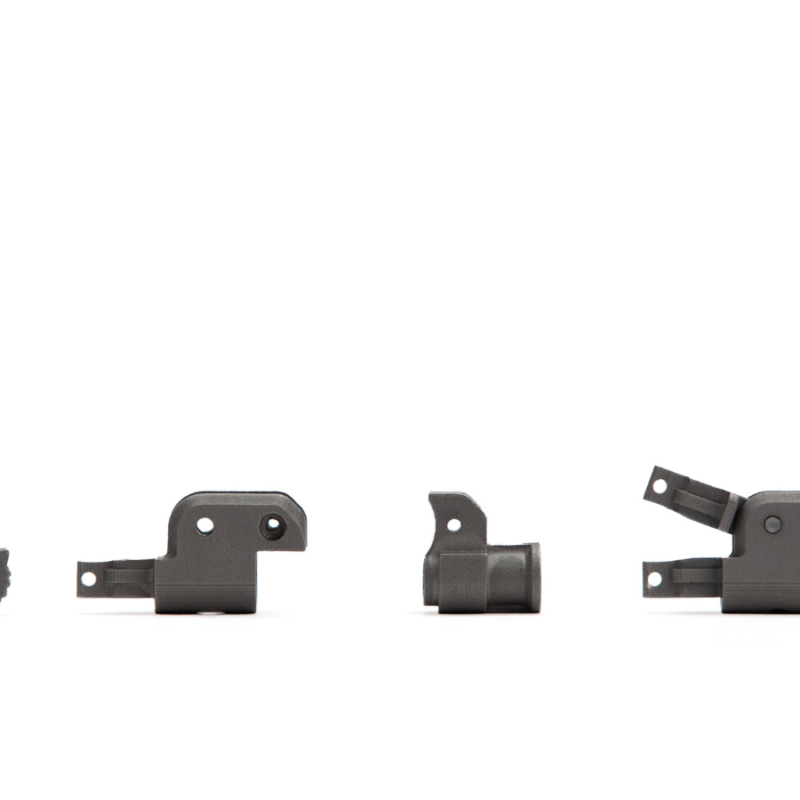

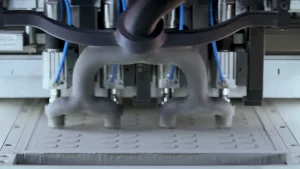

Step 2: Powder Removal and Cleaning Parts

Step 2: Powder Removal and Cleaning Parts

This metal additive manufacturing technology is capable of producing remarkably complex and “near net shape” parts for the right application that can be easily broken out, cleaned and depowdered.

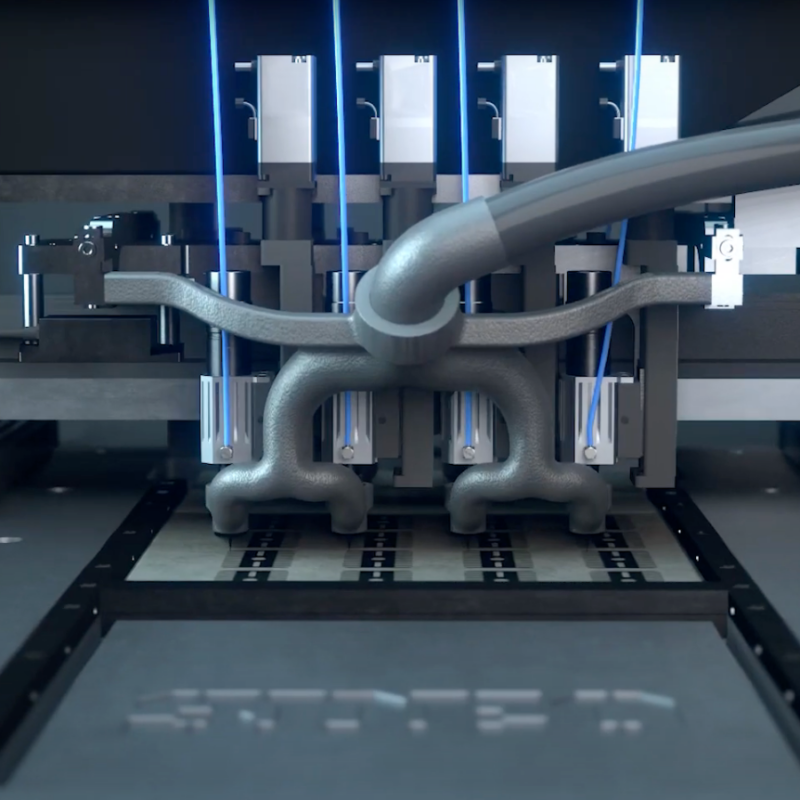

Step 3: Sintering

Step 3: Sintering

After depowdering, the printed parts are sent into a furnace to be sintered.

Step 4: Post Processing

Step 4: Post Processing

Finally, the parts are post processed through heat treating and surface finishing to reveal their final form.

“3DEO is thrilled to be partnering with LACE and Jenny Wu on this high quality, first edition chain link bracelet. By partnering with 3DEO, Jenny and her team were able to take advantage of the end-to-end services that 3DEO offers: ideation and design, prototyping, and production manufacturing. We’re excited to help bring this fresh and unique product to launch.” – Matt Sand, President and Co-founder of 3DEO

Explore the Entire Process Behind the Scenes

See the making of Link with your own eyes.

Link bracelet is available for pre-order now.

Be among the first to try this unique fully 3D printed chain bracelet.

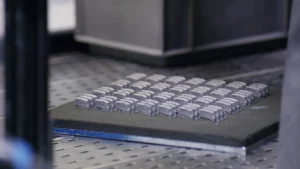

Above: Link bracelet and its individual link pieces

Above: Link bracelet and its individual link pieces