If you missed our webinar, you can access the recording here: High-Performance Metal 3D Printing

Here are some highlights from the webinar:

- How can companies be convinced to use metal 3D Printing in production? The focus of the webinar was on presenting the testing results of production metal 3D printed parts against both traditional manufacturing and other additively manufactured parts through typical ASTM testing methodologies including density, hardness, tensile strength, impact, and surface finish.

- Metal 3D Printing process overview: Specific details of 3DEO’s proprietary metal 3D Printing process and how the high densification and superior material properties are achieved.

- Step-by-step explanation of the testing methodologies used: In-depth explanation of the different testing methods used according to the ASTM standards for both as-sintered and heat treated specimens.

- How does high density affect material properties? The testing results directly show how increased densification improve material properties for 17-4PH stainless steel well over the existing metal injection molding typical values for MPIF Standard 35.

3DEO’s Intelligent Layering

3DEO’s technology, Intelligent Layering®, is designed specifically for serial production. Our tolerances, material properties, and surface finish are on par with CNC machining. 3DEO specializes in small complex parts (~1 in3 or smaller) in 17-4PH stainless steel.

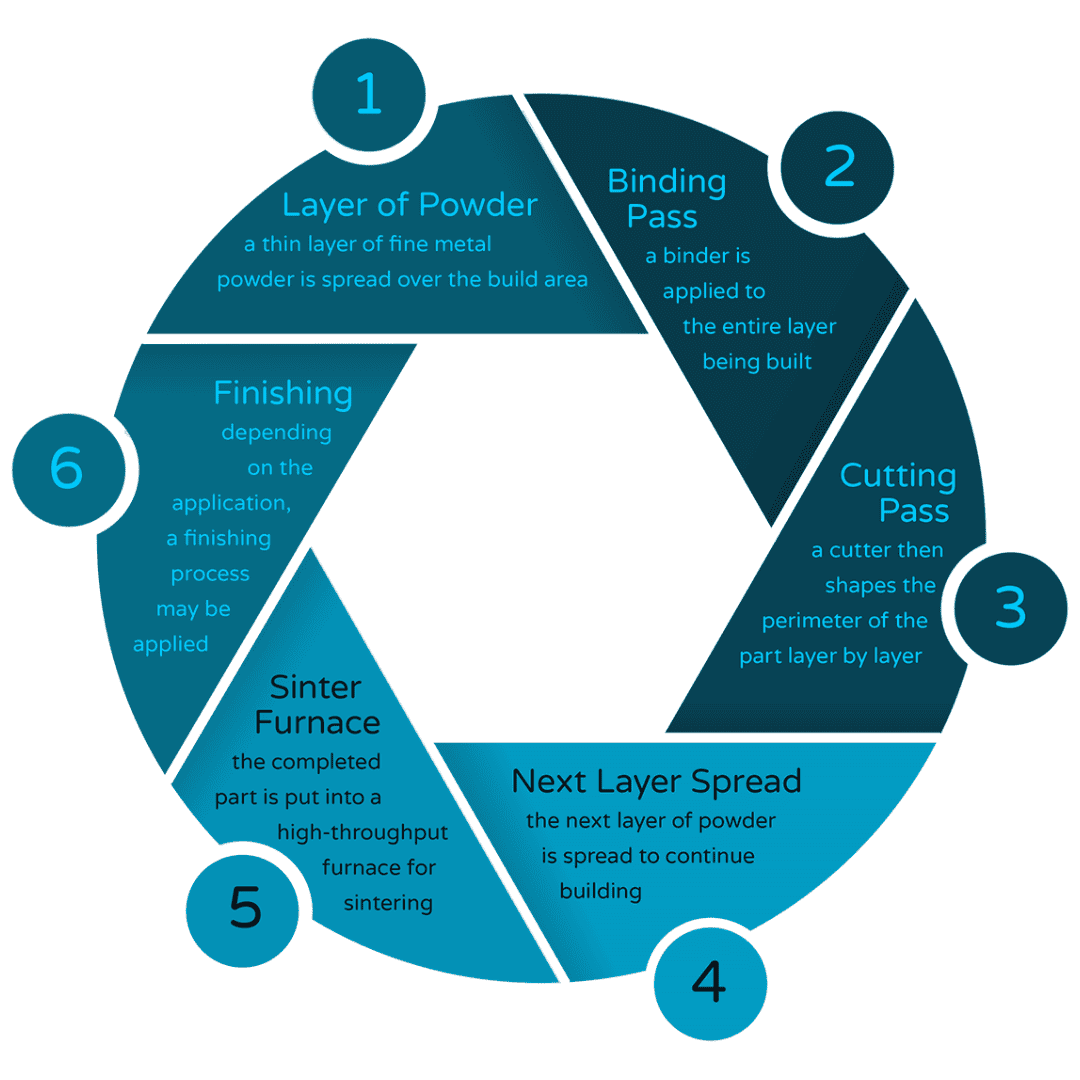

The Intelligent Layering process goes as follows:

3DEO’s two technical co-founders invented Intelligent Layering because they were discouraged by binder jetting’s inability to achieve high-volume production, repeatability, and low cost. The patented spray technology has many technical advantages over binder jetting. The elimination of droplet effects on the green parts results in consistent powder packing, binder to powder ratio, and no cross-sectional area effects. The spray also expands the variety of binder we can use and improves the dimensional stability of the green part.

The “Intelligent” part of Intelligent Layering comes from the ability of the process to use a dynamic layer thickness approach to building a part or the elimination of the concept of a layer entirely. Intelligent Layering uses a cutting tool from the top that forms parts in three dimensions, eliminating stair stepping entirely.

To learn more about 3DEO’s Intelligent Layering, watch the webinar now.