AM Shows and Disruptive Magazine have decided to join forces in the lead up to Additive Manufacturing Americas 2017 and bring you the Exhibitor Spotlight Q&A series. This is an opportunity for exhibitors to share their views on the future of industrial additive manufacturing and 3D printing as well as a preview of what you’ll see on the show floor. If you like what you read, all the more reason to come and meet them December 6-8, in Pasadena, California.

AM Shows and Disruptive Magazine have decided to join forces in the lead up to Additive Manufacturing Americas 2017 and bring you the Exhibitor Spotlight Q&A series. This is an opportunity for exhibitors to share their views on the future of industrial additive manufacturing and 3D printing as well as a preview of what you’ll see on the show floor. If you like what you read, all the more reason to come and meet them December 6-8, in Pasadena, California.

Meet Lance Kallman, Vice President (VP) of business development at 3DEO – 3DEO’s breakthrough Intelligent Layering technology unlocks high-volume metal additive manufacturing (AM) by drastically reducing final part cost. Leveraging its unique technology as a parts supplier, 3DEO sells high-volume, high-value metal parts to manufacturers with a variety of applications from a wide range of industries.

What do you consider to be the key potential for OEMs adopting or optimizing the use of AM/3D printing and advanced design and manufacturing technologies, and how is your company positioning itself to realize this potential?

The potential for metal 3D printing with OEMs is tremendous and includes printing on demand to reduce production lead times and inventory levels. It also helps companies go to market more quickly by iterating on new designs in real time, while also allowing for parts to be designed outside of traditional manufacturing. We have positioned ourselves as a parts supplier with our low-cost, high-volume metal AM technology so that we can directly provide parts to OEMs and allow them to reap the benefits of AM without the large capital investment required to purchase and operate in-house AM machines.

What products and/or services will you be showcasing at Additive Manufacturing Americas 2017?

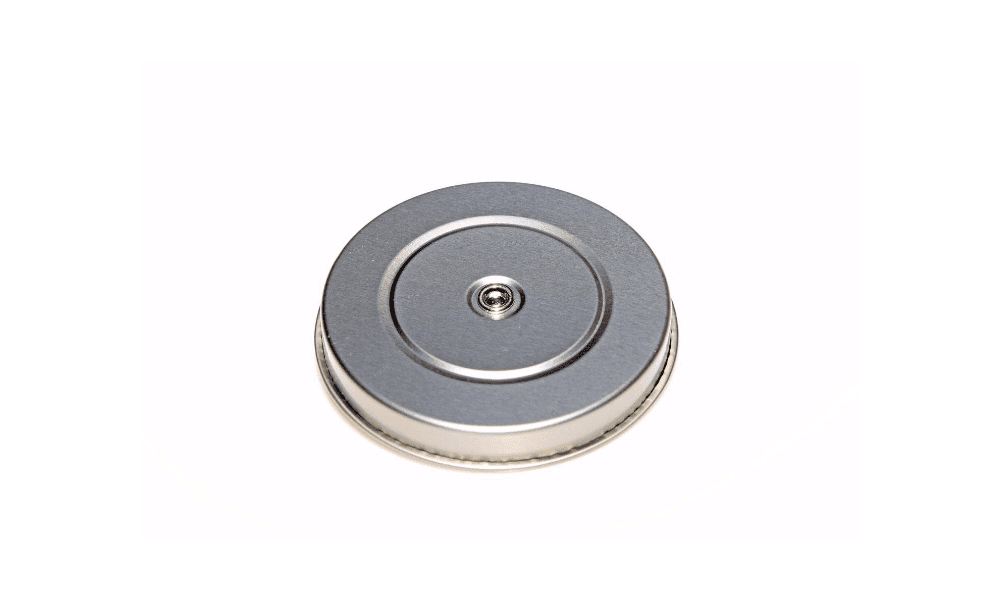

We will be showcasing metal parts printed using our Intelligent Layering technology, which will demonstrate our best-in-class surface finish and complex part geometry capabilities. We will also have case studies showing specifically how we have helped customers save money, reduce lead times and achieve part geometries not possible with traditional manufacturing techniques—all this for end-use parts and in high volumes not previously seen in metal AM.

What influenced your decision to exhibit at Additive Manufacturing Americas 2017?

This will be our first Additive Manufacturing Americas show but anecdotally we have heard this is a great show for AM parts suppliers.

What in your opinion will be the next big advance for AM/3D printing?

The next big advance in metal AM will likely be technologies that continue to drive down the cost-per-part and increase the throughput.

If you could say one thing to convince OEMs to embrace AM/3D printing and the ecosystem of allied technologies, what would it be?

I would point to GE and how they recently invested 2 billion USD in buying two AM companies. They also released a stated strategy where they will pull 5 billion USD out of their supply chain by 2020 with AM technology. If OEMs aren’t trying to understand how AM can complement their current manufacturing technologies in the factory of the future, they are already behind

As seen on www.amshow-americas.com.

Address: 14000 Van Ness Ave, Ste C, Gardena, California, USA, 90249

Phone number: +1 844 49 METAL (63825)

Website: www.3deo.co / Email: [email protected]

To learn more about 3DEO stop by stand 121 this December 6-8 in Pasadena, CA during Additive Manufacturing Americas 2017.